| Availability: | |

|---|---|

| Quantity: | |

40000L Aluminum Fuel Tanker Semi Trailer for Sale

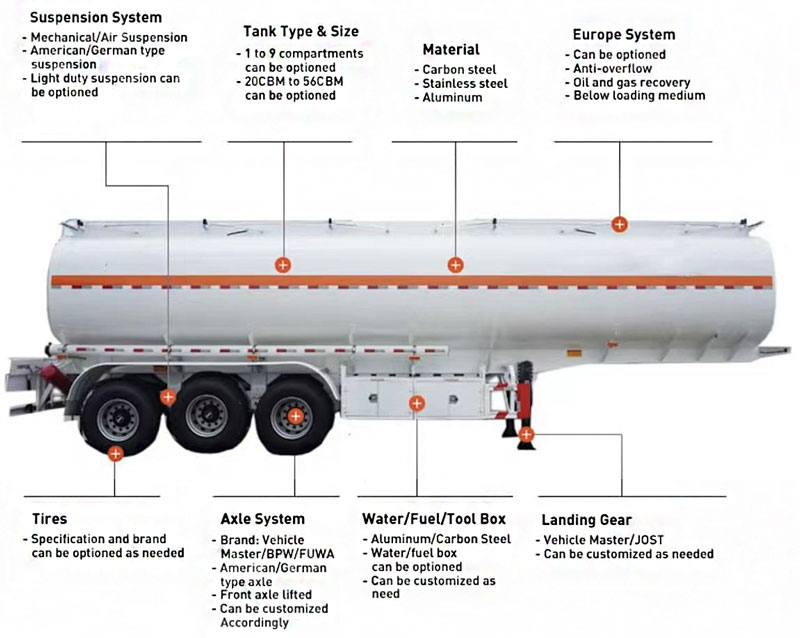

This 40000L aluminum fuel tanker semi trailer is manufactured by Vehicle Master and offered at factory-direct pricing.

The tank body is made of high-quality aluminum alloy and combined with precision welding technology. It features light tare weight, strong load capacity, and excellent sealing performance with no leakage risk. It is suitable for the efficient transportation of food-grade liquid cargo such as milk and edible oil, as well as various clean liquid materials.

As a semi-trailer factory, this 40000L aluminum fuel tanker semi trailer supports personalized customization. The capacity can be customized within the range of 20,000–60,000 liters, equipped with 2/3/4 axles, and can be divided into 1–9 independent compartments as required. In addition to aluminum alloy, carbon steel and stainless steel materials are also available. Advanced function options such as oil and gas recovery, thermal insulation, and heating systems are provided to precisely match diversified transportation requirements.

Applications

Food-Grade Liquid Transportation: Suitable for transporting milk and edible oil. The aluminum alloy material is clean and non-toxic, ensuring food safety.

Chemical Transportation: Used for transporting low-corrosive liquid chemical raw materials with sealed and pollution-free performance.

Clean Energy Transportation: Suitable for transporting biodiesel, ethanol, and other clean energy products.

Finished Fuel Distribution: The lightweight advantage increases effective payload, efficiently serving fuel supply for gas stations, airports, and construction sites.

Special Cargo: Insulation and heating functions are available to support the transportation of heavy oil, asphalt, and other liquids.

Specifications

Model: 40000L Aluminum Fuel Tanker Semi Trailer

Standard Capacity: 40000L

Customizable Capacity: 20000–60000L

Standard Axles: 3 axles, 13/16 tons per axle, FUWA/BPW

Custom Axles: 2/3/4 axles

Compartments: 1–9 compartments (customizable)

Tank Material: Aluminum alloy (carbon steel and stainless steel optional)

European System: Available

Thermal: Available

Manhole: Anti-Explosion

Lifted Axle: Available

Vehicle Examination: X-RAY Room Examination

Tank Shape: D Style / Round Style

Pumping System: Optional self-priming pump / stainless steel gear pump

Brake System: WABCO air brake + ABS system

Suspension System: Leaf spring suspension / Air suspension

Tire Specification: 12R22.5 / 11.00R20

Tire Quantity: 12 pieces (4 tires per axle)

King Pin: #50 (2") / #90 (3.5"), JOST / Other Brand

Landing Gear: 28 Tons Two Speed, JOST / Other Brand

Safety Configuration: Overfill valve, static grounding device, oil and gas recovery interface (optional)

Price Range

As a semi-trailer manufacturer and dealer, the price range of our fuel tanker semi trailers is USD 12,000–25,000. The key pricing factors include: tank material grade (differences among aluminum alloy, carbon steel, and stainless steel), tank capacity and compartment configuration, whether advanced functions such as oil and gas recovery, insulation, and heating are added, brand selection of core components such as pumping systems, and customer purchase quantity.

If you would like to purchase a fuel tanker semi trailer at factory pricing or customize it according to your operational requirements, please contact us via website message or WhatsApp (+86-18866100060).

Core Manufacturing Processes

Welding: The longitudinal seams and circumferential seams of the tank body are all welded automatically by industrial robots. With high welding precision, the welds are flat, uniform, and smoothly formed, effectively enhancing the overall structural integrity and durability. Welding parameters are optimized specifically for aluminum alloy characteristics to achieve seamless sealing, completely eliminating the risk of liquid leakage. After welding, strict airtightness and hydrostatic pressure tests are conducted to ensure transportation safety.

Painting: After tank welding is completed, professional surface treatment is carried out, followed by spraying high-performance polyurethane combined coating. This coating has excellent adhesion to aluminum alloy surfaces, forming a tough, dense, and elastic paint film with full gloss and fine texture. It provides outstanding scratch resistance and corrosion resistance, suitable for various complex climates and operating environments.

Main Features

Material: The tank is made of aluminum alloy with low self-weight, allowing more legal payload. High-quality carbon steel and stainless steel options are also available.

Compartment Design: Supports customization of 1–9 independent compartments, enabling the transportation of multiple different liquids in a single trip, improving operational flexibility and preventing cross-contamination.

Pumping System: Equipped with a dedicated high-efficiency pumping system featuring strong suction power, fast unloading speed, no residue, and simple, convenient operation.

Insulation and Heating Function: Optional polyurethane foam insulation layer effectively maintains internal tank temperature and prevents cargo solidification. Optional thermal oil or electric tracing heating systems can heat and liquefy high-viscosity liquids that are prone to solidification.

Oil and Gas Recovery: Optional oil and gas recovery system recovers volatilized oil and gas during loading and unloading, reducing material loss and improving economic efficiency.

Overfill Valve: Standard high-precision overfill sensors automatically alarm and cut off feeding when the preset loading level is reached.

Suspension System: Leaf spring suspension or air suspension options are available. Leaf spring suspension offers better economy, while air suspension provides better stability.

Purchase Advantages

Factory Price Advantage: Purchasing from us means buying directly from the factory with no middleman price difference, ensuring the best investment experience.

Free Customization: With a professional engineering team, we provide full-process free customization services, precisely matching materials, capacity, and functional configurations.

Warranty: We provide one-year free warranty service. All non-human-caused failures are eligible for free repair and component replacement.

Lifetime Spare Parts Supply: We provide continuous and stable original spare parts supply support, ensuring full lifecycle operation of the trailer.

Contact for Purchase

Purchasing directly from the manufacturer Vehicle Master is the best way to obtain a high-quality, highly customized aluminum tanker trailer. Whether you have purchasing inquiries, customization discussions, or other related questions, please contact us immediately. Our expert team is always ready to provide detailed product consultation and exclusive quotations. You can contact us via website message or WhatsApp (+86-18866100060).

40000L Aluminum Fuel Tanker Semi Trailer for Sale

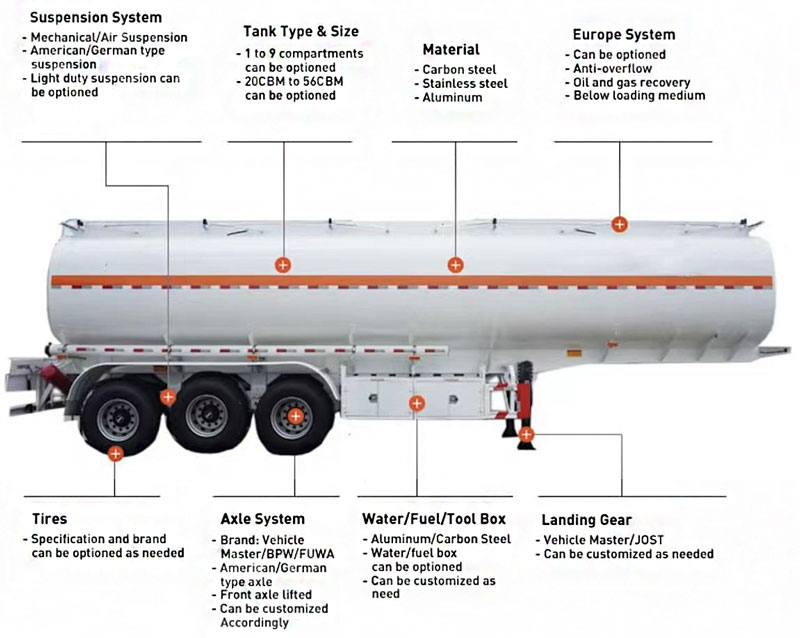

This 40000L aluminum fuel tanker semi trailer is manufactured by Vehicle Master and offered at factory-direct pricing.

The tank body is made of high-quality aluminum alloy and combined with precision welding technology. It features light tare weight, strong load capacity, and excellent sealing performance with no leakage risk. It is suitable for the efficient transportation of food-grade liquid cargo such as milk and edible oil, as well as various clean liquid materials.

As a semi-trailer factory, this 40000L aluminum fuel tanker semi trailer supports personalized customization. The capacity can be customized within the range of 20,000–60,000 liters, equipped with 2/3/4 axles, and can be divided into 1–9 independent compartments as required. In addition to aluminum alloy, carbon steel and stainless steel materials are also available. Advanced function options such as oil and gas recovery, thermal insulation, and heating systems are provided to precisely match diversified transportation requirements.

Applications

Food-Grade Liquid Transportation: Suitable for transporting milk and edible oil. The aluminum alloy material is clean and non-toxic, ensuring food safety.

Chemical Transportation: Used for transporting low-corrosive liquid chemical raw materials with sealed and pollution-free performance.

Clean Energy Transportation: Suitable for transporting biodiesel, ethanol, and other clean energy products.

Finished Fuel Distribution: The lightweight advantage increases effective payload, efficiently serving fuel supply for gas stations, airports, and construction sites.

Special Cargo: Insulation and heating functions are available to support the transportation of heavy oil, asphalt, and other liquids.

Specifications

Model: 40000L Aluminum Fuel Tanker Semi Trailer

Standard Capacity: 40000L

Customizable Capacity: 20000–60000L

Standard Axles: 3 axles, 13/16 tons per axle, FUWA/BPW

Custom Axles: 2/3/4 axles

Compartments: 1–9 compartments (customizable)

Tank Material: Aluminum alloy (carbon steel and stainless steel optional)

European System: Available

Thermal: Available

Manhole: Anti-Explosion

Lifted Axle: Available

Vehicle Examination: X-RAY Room Examination

Tank Shape: D Style / Round Style

Pumping System: Optional self-priming pump / stainless steel gear pump

Brake System: WABCO air brake + ABS system

Suspension System: Leaf spring suspension / Air suspension

Tire Specification: 12R22.5 / 11.00R20

Tire Quantity: 12 pieces (4 tires per axle)

King Pin: #50 (2") / #90 (3.5"), JOST / Other Brand

Landing Gear: 28 Tons Two Speed, JOST / Other Brand

Safety Configuration: Overfill valve, static grounding device, oil and gas recovery interface (optional)

Price Range

As a semi-trailer manufacturer and dealer, the price range of our fuel tanker semi trailers is USD 12,000–25,000. The key pricing factors include: tank material grade (differences among aluminum alloy, carbon steel, and stainless steel), tank capacity and compartment configuration, whether advanced functions such as oil and gas recovery, insulation, and heating are added, brand selection of core components such as pumping systems, and customer purchase quantity.

If you would like to purchase a fuel tanker semi trailer at factory pricing or customize it according to your operational requirements, please contact us via website message or WhatsApp (+86-18866100060).

Core Manufacturing Processes

Welding: The longitudinal seams and circumferential seams of the tank body are all welded automatically by industrial robots. With high welding precision, the welds are flat, uniform, and smoothly formed, effectively enhancing the overall structural integrity and durability. Welding parameters are optimized specifically for aluminum alloy characteristics to achieve seamless sealing, completely eliminating the risk of liquid leakage. After welding, strict airtightness and hydrostatic pressure tests are conducted to ensure transportation safety.

Painting: After tank welding is completed, professional surface treatment is carried out, followed by spraying high-performance polyurethane combined coating. This coating has excellent adhesion to aluminum alloy surfaces, forming a tough, dense, and elastic paint film with full gloss and fine texture. It provides outstanding scratch resistance and corrosion resistance, suitable for various complex climates and operating environments.

Main Features

Material: The tank is made of aluminum alloy with low self-weight, allowing more legal payload. High-quality carbon steel and stainless steel options are also available.

Compartment Design: Supports customization of 1–9 independent compartments, enabling the transportation of multiple different liquids in a single trip, improving operational flexibility and preventing cross-contamination.

Pumping System: Equipped with a dedicated high-efficiency pumping system featuring strong suction power, fast unloading speed, no residue, and simple, convenient operation.

Insulation and Heating Function: Optional polyurethane foam insulation layer effectively maintains internal tank temperature and prevents cargo solidification. Optional thermal oil or electric tracing heating systems can heat and liquefy high-viscosity liquids that are prone to solidification.

Oil and Gas Recovery: Optional oil and gas recovery system recovers volatilized oil and gas during loading and unloading, reducing material loss and improving economic efficiency.

Overfill Valve: Standard high-precision overfill sensors automatically alarm and cut off feeding when the preset loading level is reached.

Suspension System: Leaf spring suspension or air suspension options are available. Leaf spring suspension offers better economy, while air suspension provides better stability.

Purchase Advantages

Factory Price Advantage: Purchasing from us means buying directly from the factory with no middleman price difference, ensuring the best investment experience.

Free Customization: With a professional engineering team, we provide full-process free customization services, precisely matching materials, capacity, and functional configurations.

Warranty: We provide one-year free warranty service. All non-human-caused failures are eligible for free repair and component replacement.

Lifetime Spare Parts Supply: We provide continuous and stable original spare parts supply support, ensuring full lifecycle operation of the trailer.

Contact for Purchase

Purchasing directly from the manufacturer Vehicle Master is the best way to obtain a high-quality, highly customized aluminum tanker trailer. Whether you have purchasing inquiries, customization discussions, or other related questions, please contact us immediately. Our expert team is always ready to provide detailed product consultation and exclusive quotations. You can contact us via website message or WhatsApp (+86-18866100060).