In order to have a smooth inspection process, the following regulations and methods are proposed, which must be carefully implemented in the operation.

Precautions During Inspection

The usual inspections are carried out in an empty state unless specified.

When the wheel is to be lifted, the axle should be jacked up at the same time. The jack location should be close to the leaf spring.

The parts in contact with the jacks should be padded with thick steel plates or planks to prevent local overloading or slipping.

Check All Pipelines

Connect the brake air system of the semi-trailer and the brake air system of the tractor.

Increase the air pressure to the specified pressure, and check the air pressure from the pressure gauge in the tractor cab or the pressure gauge installed in the emergency braking system.

Step on the brake pedal of the tractor, and check whether the pressure drop exceeds 50Kpa per hour (the engine does not run). If it exceeds 50kpa per hour, the cause of the air leakage should be found out and repaired. When the pressure of the gas storage tank is lower than 650Kpa, it is not allowed to start driving.

If the pressure drop exceeds the specified value, apply soapy water to the connection part of the pipeline to check for air leakage. If there is air leakage, tighten the part or replace the parts.

Turn off the conversion cock of the emergency system of the tractor, then unplug the emergency brake air pipe of the semi-trailer and check whether it is in brake. If it cannot brake automatically, the emergency relay valve is faulty.

Check The Emergency Relay Valve

During various inspections of the braking system, check whether there is any air leakage in each part of the emergency relay. Make sure the diameter of the soap bubble does not exceed 3 mm within 3 seconds.

If the tractor has a disconnect switch, first turn off the disconnect switch of the tractor, then remove the quick connector connected to the airline of the semi-trailer on the tractor. Check whether the brake is working. If not, the valve is faulty.

Then connect the quick connector of the charging pipe. If the tractor has a disconnected switch, open the disconnect switch and check whether the brakes are automatically released.

Check whether the exhaust gas is discharged from the exhaust port when the brake is released. If so, it is normal.

If the action is not flexible, check whether the quick release valve (if any) is faulty. Otherwise, it should be replaced with emergency relay valve or quick release valve (if present).

Alerts

Users are not allowed to modify the brake air system without permission, including adding a water spray system, and privately connecting the air source from the trailer air tank, which will affect the quality of the brakes and even bring about more hidden brake failures.

In the cold winter season, too much water in the vehicle braking system will easily cause the brake network (relay test, ABS valve) to be blocked or frozen, which will seriously affect the braking effect or cause the valve body to malfunction, resulting in full braking. As a result, the vehicle cannot be driven normally. In severe cases, it may damage the vehicle or cause a traffic accident!

In the cold winter season, it is recommended to discharge the accumulated water in each gas storage tank of the semi-discharge vehicle every day to minimize the amount of accumulated water in the braking system!

Check the efficiency of the air dryer of the tractor. If the hand dryer fails, replace the drying cylinder in time to ensure that the brake air is dry!

Check The Brake Chamber

When checking the brake, check whether the push rod of the brake air chamber moves flexibly and whether it is within the specified stroke range (standard working stroke is 30-35mm). Refer to the axle manual for the specific value. If the stroke exceeds 50mm, it must be readjusted. In order to have the same braking effect on the left and right wheels, the stroke of the left and right brake air chamber push rods should be as small as possible, while not exceeding 5mm.

Check whether the brake air chamber leaks under the braking state and whether there is any air leakage in the drain hole. If there is air leakage, replace the rubber diaphragm. Check the exterior for cracks and damage and replace the brake chamber if necessary.

Brake adjustment arm and brake adjustment.

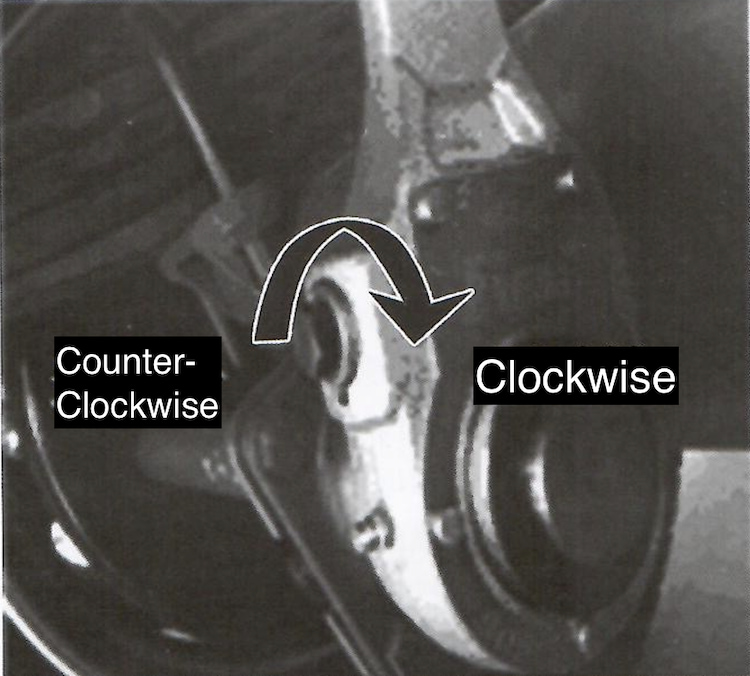

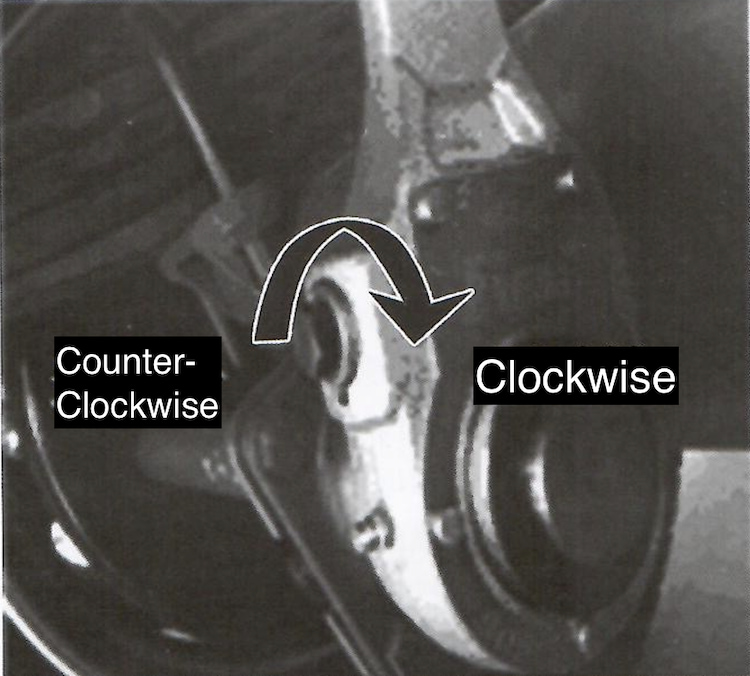

When operating the brake, check the working state of the brake adjusting arm. At the same time, check the stroke of the push rod. If the stroke is too large, it means that the gap between the brake drum and the brake shoe is too large, and should be adjusted according to the method (see Figure 1).

When adjusting the brake, firstly turn the adjustment pin to the right (clockwise) to make the brake shoe completely contact the brake drum. At this time, the angle between the push rod of the brake air chamber and the control arm should be ≥90°. Then reverse (counterclockwise) the pin shaft to make the push rod travel a specified value, and then use the position fixing sleeve to position the pin shaft (see the adjustment method of the axle adjustment arm for details).

Special Reminder

After adjusting the brake, check the rotation state of the wheel. The wheel must rotate freely.

It is not easy to ensure the same clearance when adjusting the brakes of each wheel so the wheels do not deviate when the brakes are tested after adjustment.

If the semi-trailer is equipped with an automatic brake clearance adjustment arm, the adjustment arm does not need to be calibrated.

Check The Gas Tank

After driving, be sure to unscrew the water cock at the bottom of the air tank to drain the internal water.

When the water is drained, the internal gas will be discharged at the same time. If the brake chamber and the emergency relay valve are engaged due to excessive exhaust gas, the gas should be re-inflated to keep the internal pressure of the gas storage tank at a constant value.

Check Pipes and Joints

Check whether the pipes and joints are cracked or damaged, and repair or replace them in time.

Axle Inspection

Check the axles and tires for damage, bending and discoloration, repair and replace, tighten and adjust the wheel nuts if necessary.

Use a jack to lift the axle of the semi-trailer so that the tires are off the ground.

Rotate the axle hub, tighten the inner nut with a torque of 310N.m, and then reverse it by 1/8~1/6 turn.

Rotate the wheel hub, tap the wheel hub (wheel bearing position) lightly with a hammer to check whether it rotates smoothly. If the resistance is large, loosen the inner nut slightly until the wheel hub can rotate freely without obvious swing, and then plug it in cotter pin to lock the lock nut.

Apply sealant to the hubcap and install the hubcap.

Always check the tightness of the wheel nuts. If they are loose, tighten them with a tightening torque of 600-630v.

Tire Maintenance

Whether the tire pressure is appropriate greatly affects the life and safety of the tire. So, the specified tire pressure should be maintained including the spare tire.

Depending on the load, road surface and braking state, the tire wear is also different. In order to make the tire wear consistent, the tire installation position should be changed regularly (every 5000 kilometers) (see Figure 19).

Check the tightness of the wheel nuts daily and tighten them if necessary.

Figure 2. Direction of Tire Swap

Special Reminder

Insufficient inflation pressure will result in:

Shortened tire life

Accelerated tire wear, especially abnormal wear of tire shoulders

The curtain layer is cut off and separated from the rubber and the shoulder will be broken

Increased fuel consumption

When driving at high speed (over 100km/h), the tread pattern will drop blocks due to centrifugal force. When the inflation pressure is too high, it will cause side slip, cut or blowout, and accelerated wear of the tread center.