| Availability: | |

|---|---|

| Quantity: | |

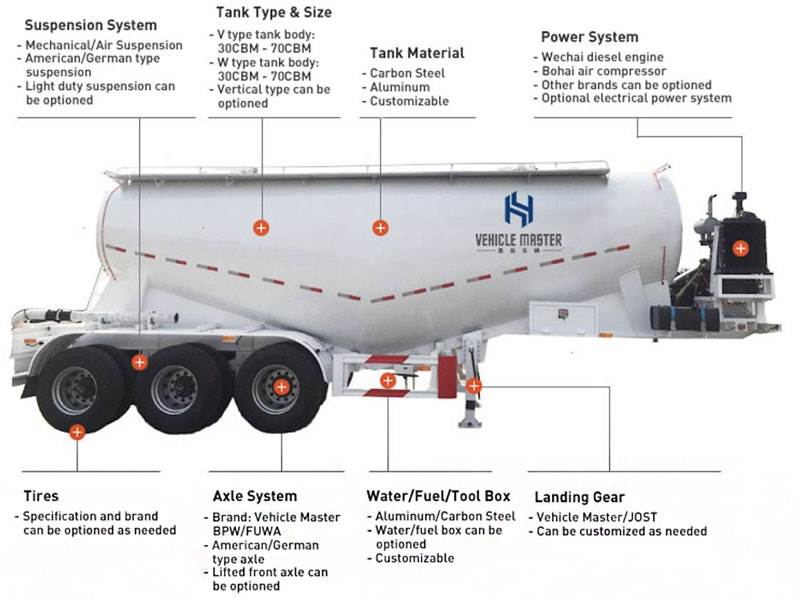

Bulk Cement Tanker Trailer for Sale in Kenya

This bulk cement tanker trailer manufactured by Vehicle Master is designed specifically to comply with regulations in Kenya, Uganda, and other African countries.

It supports customizable capacity from 30 to 70 cubic meters, equipped with 2/3/4/5 axles, and optional 1/2/3 independent compartments. It adopts a high-power pneumatic discharge system, provides both V-shaped and W-shaped tanker designs, and offers carbon steel and aluminum alloy tank materials to meet different transportation needs.

As a semi trailer factory, we offer this bulk cement tanker trailer at factory-direct prices. Made with high-quality steel and branded components, combined with advanced welding and painting processes, it significantly enhances tanker durability and air tightness, effectively preventing cement leakage and adapting to the demanding African transportation environments.

Applications

Cement Transportation: Specially designed for bulk cement, ensuring dry and moisture-proof protection.

Fly Ash Transportation: Suitable for efficient fly ash transportation in thermal power plants.

Mineral Powder Transportation: Reliable transport of various mineral powders with excellent leak-proof performance.

Chemical Powder Transportation: Suitable for transporting non-hazardous chemical powders.

Agricultural Product Transportation: Professionally designed for transporting powdered agricultural products such as flour.

Specifications

Tank Capacity: 30-70CBM (customizable)

Axle Configuration: 2/3/4/5 axles, 13/16 tons per axle, FUWA/BPW

Compartment Options: 1/2/3 compartments

Tank Material: Carbon Steel/Aluminum

Tanker Dish End Thickness: 5mm/6mm

Tanker Body Thickness: 4mm/5mm

Engine: Weichai 4102

Air Compressor: Bohai 12CBM/min

Discharge Speed: 1.2-1.8 Tons/Minute

Tire Size: 12R22.5 * 8/12/16/20 Pieces, Brand Optional

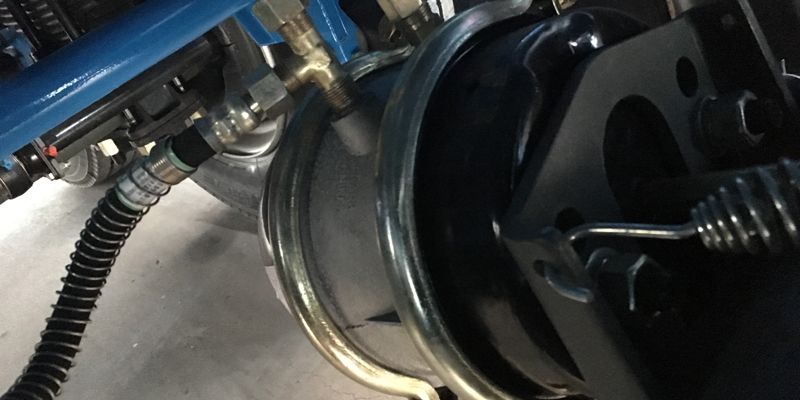

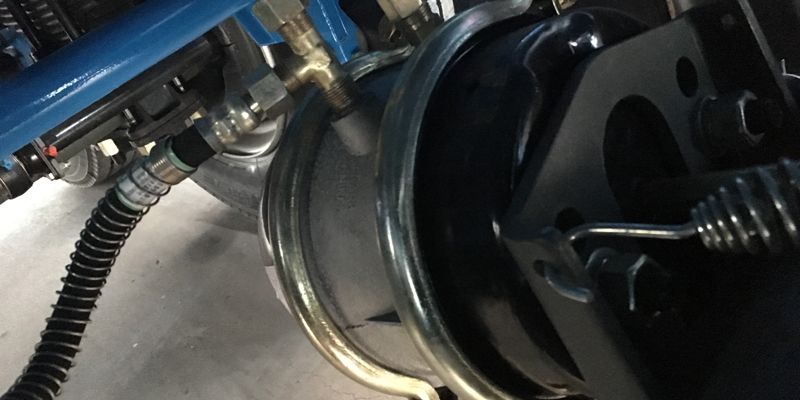

Brake System: WABCO Air Brake (ABS Optional)

King Pin: 2″/3.5″ JOST

Landing Gear: 28 Tons Two Speed, JOST/Other Brand

Vehicle Painting: Polyurethane Combination Painting

Price Range

As a semi trailer factory, the price of our bulk cement tanker trailer ranges from USD 10,000 to 35,000. Different capacities and functions will lead to price differences. Customized large-capacity 70CBM, aluminum alloy tank upgrades, 5-axle reinforced configuration, 3-compartment design, imported discharge components, and higher-end production processes will increase the price.

If you want to get more customized specifications or purchase bulk cement tanker trailers at factory prices, please leave a message on our website or contact us via WhatsApp (+86-18866100060).

Core Manufacturing Process

Welding: Automatic robotic welding technology is used to handle tank seams. By precisely controlling welding parameters, it ensures excellent penetration and weld formation, significantly enhancing structural integrity and sealing performance. This process effectively extends the service life of the tank, especially suitable for African environments.

Painting: Polyurethane combination painting process is used. The two-component coating is accurately mixed and atomized through specialized equipment to form a dense and tough protective layer. This coating provides excellent hardness and long-lasting gloss, effectively resisting sun exposure, rain, stone impact, and chemical corrosion during long-distance transportation, reducing maintenance costs.

Main Features

Tank Material: Available in carbon steel and aluminum. Carbon steel is economical and wear-resistant, while aluminum alloy is lighter, providing more payload.

V or W Tank Shape: V-shape provides simple structure and low discharge residue; W-shape offers larger capacity.

Compartment Options: 1/2/3 compartment customization available. Suitable for carrying different cement specifications simultaneously, preventing cross-contamination.

Discharge System: Equipped with pneumatic discharge system powered by Weichai diesel engine and Bohai air compressor, easy to operate and highly efficient.

Brake System: WABCO air brake system with ABS option. Responsive performance ensures smooth and safe driving.

King Pin: Equipped with JOST king pin, high strength, durable, and highly compatible with mainstream tractors.

Color and Logo: Customizable corporate branding and color schemes to enhance company image.

After-Sales Service

When purchasing our bulk cement tanker trailer, we provide one-year free warranty. Any failures caused by manufacturing defects are covered with free repair and parts replacement.

We provide lifetime supply of original spare parts to ensure compatibility and offer professional maintenance guidance.

Contact Us

We are the manufacturer of bulk cement tanker trailers. By choosing us, you will enjoy factory-direct pricing with no middleman markup. If you need detailed configuration lists, customized solutions, or real-time quotations, feel free to contact us. Our professional team will provide comprehensive support.

You can leave a message on our website or contact us via WhatsApp (+86-18866100060).

FAQ

Q1: Does the product comply with African regulations?

A: Yes. Our products can be designed and manufactured according to local standards of African countries to fully meet local transportation requirements.

Q2: Can it transport other powdered materials?

A: Absolutely. In addition to cement, it is also suitable for transporting various types of powdered materials, including mineral powders and agricultural products.

Q3: Aluminum alloy tanks are more expensive than carbon steel. How about long-term cost-effectiveness?

A: Aluminum alloy is 30% lighter, reducing fuel consumption by 15% per trip. Based on annual transportation capacity in Kenya, the cost difference can be recovered within 1-2 years, and it has a longer anti-corrosion lifespan.

Q4: How is unloading efficiency guaranteed?

A: Equipped with a high-efficiency pneumatic discharge system, it ensures fast unloading speed and low residue, significantly improving operational efficiency and meeting frequent loading and unloading needs.

Q5: What is the production and delivery time for customized models?

A: Regular customization takes about 25-30 days, and special configurations take about 30-40 days.

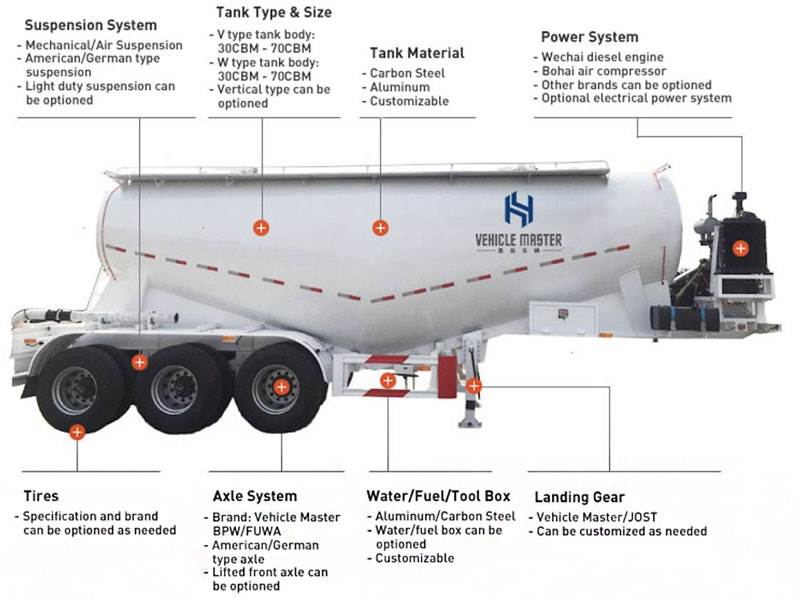

Bulk Cement Tanker Trailer for Sale in Kenya

This bulk cement tanker trailer manufactured by Vehicle Master is designed specifically to comply with regulations in Kenya, Uganda, and other African countries.

It supports customizable capacity from 30 to 70 cubic meters, equipped with 2/3/4/5 axles, and optional 1/2/3 independent compartments. It adopts a high-power pneumatic discharge system, provides both V-shaped and W-shaped tanker designs, and offers carbon steel and aluminum alloy tank materials to meet different transportation needs.

As a semi trailer factory, we offer this bulk cement tanker trailer at factory-direct prices. Made with high-quality steel and branded components, combined with advanced welding and painting processes, it significantly enhances tanker durability and air tightness, effectively preventing cement leakage and adapting to the demanding African transportation environments.

Applications

Cement Transportation: Specially designed for bulk cement, ensuring dry and moisture-proof protection.

Fly Ash Transportation: Suitable for efficient fly ash transportation in thermal power plants.

Mineral Powder Transportation: Reliable transport of various mineral powders with excellent leak-proof performance.

Chemical Powder Transportation: Suitable for transporting non-hazardous chemical powders.

Agricultural Product Transportation: Professionally designed for transporting powdered agricultural products such as flour.

Specifications

Tank Capacity: 30-70CBM (customizable)

Axle Configuration: 2/3/4/5 axles, 13/16 tons per axle, FUWA/BPW

Compartment Options: 1/2/3 compartments

Tank Material: Carbon Steel/Aluminum

Tanker Dish End Thickness: 5mm/6mm

Tanker Body Thickness: 4mm/5mm

Engine: Weichai 4102

Air Compressor: Bohai 12CBM/min

Discharge Speed: 1.2-1.8 Tons/Minute

Tire Size: 12R22.5 * 8/12/16/20 Pieces, Brand Optional

Brake System: WABCO Air Brake (ABS Optional)

King Pin: 2″/3.5″ JOST

Landing Gear: 28 Tons Two Speed, JOST/Other Brand

Vehicle Painting: Polyurethane Combination Painting

Price Range

As a semi trailer factory, the price of our bulk cement tanker trailer ranges from USD 10,000 to 35,000. Different capacities and functions will lead to price differences. Customized large-capacity 70CBM, aluminum alloy tank upgrades, 5-axle reinforced configuration, 3-compartment design, imported discharge components, and higher-end production processes will increase the price.

If you want to get more customized specifications or purchase bulk cement tanker trailers at factory prices, please leave a message on our website or contact us via WhatsApp (+86-18866100060).

Core Manufacturing Process

Welding: Automatic robotic welding technology is used to handle tank seams. By precisely controlling welding parameters, it ensures excellent penetration and weld formation, significantly enhancing structural integrity and sealing performance. This process effectively extends the service life of the tank, especially suitable for African environments.

Painting: Polyurethane combination painting process is used. The two-component coating is accurately mixed and atomized through specialized equipment to form a dense and tough protective layer. This coating provides excellent hardness and long-lasting gloss, effectively resisting sun exposure, rain, stone impact, and chemical corrosion during long-distance transportation, reducing maintenance costs.

Main Features

Tank Material: Available in carbon steel and aluminum. Carbon steel is economical and wear-resistant, while aluminum alloy is lighter, providing more payload.

V or W Tank Shape: V-shape provides simple structure and low discharge residue; W-shape offers larger capacity.

Compartment Options: 1/2/3 compartment customization available. Suitable for carrying different cement specifications simultaneously, preventing cross-contamination.

Discharge System: Equipped with pneumatic discharge system powered by Weichai diesel engine and Bohai air compressor, easy to operate and highly efficient.

Brake System: WABCO air brake system with ABS option. Responsive performance ensures smooth and safe driving.

King Pin: Equipped with JOST king pin, high strength, durable, and highly compatible with mainstream tractors.

Color and Logo: Customizable corporate branding and color schemes to enhance company image.

After-Sales Service

When purchasing our bulk cement tanker trailer, we provide one-year free warranty. Any failures caused by manufacturing defects are covered with free repair and parts replacement.

We provide lifetime supply of original spare parts to ensure compatibility and offer professional maintenance guidance.

Contact Us

We are the manufacturer of bulk cement tanker trailers. By choosing us, you will enjoy factory-direct pricing with no middleman markup. If you need detailed configuration lists, customized solutions, or real-time quotations, feel free to contact us. Our professional team will provide comprehensive support.

You can leave a message on our website or contact us via WhatsApp (+86-18866100060).

FAQ

Q1: Does the product comply with African regulations?

A: Yes. Our products can be designed and manufactured according to local standards of African countries to fully meet local transportation requirements.

Q2: Can it transport other powdered materials?

A: Absolutely. In addition to cement, it is also suitable for transporting various types of powdered materials, including mineral powders and agricultural products.

Q3: Aluminum alloy tanks are more expensive than carbon steel. How about long-term cost-effectiveness?

A: Aluminum alloy is 30% lighter, reducing fuel consumption by 15% per trip. Based on annual transportation capacity in Kenya, the cost difference can be recovered within 1-2 years, and it has a longer anti-corrosion lifespan.

Q4: How is unloading efficiency guaranteed?

A: Equipped with a high-efficiency pneumatic discharge system, it ensures fast unloading speed and low residue, significantly improving operational efficiency and meeting frequent loading and unloading needs.

Q5: What is the production and delivery time for customized models?

A: Regular customization takes about 25-30 days, and special configurations take about 30-40 days.